|

Service

|

Location£ºHome > Service |

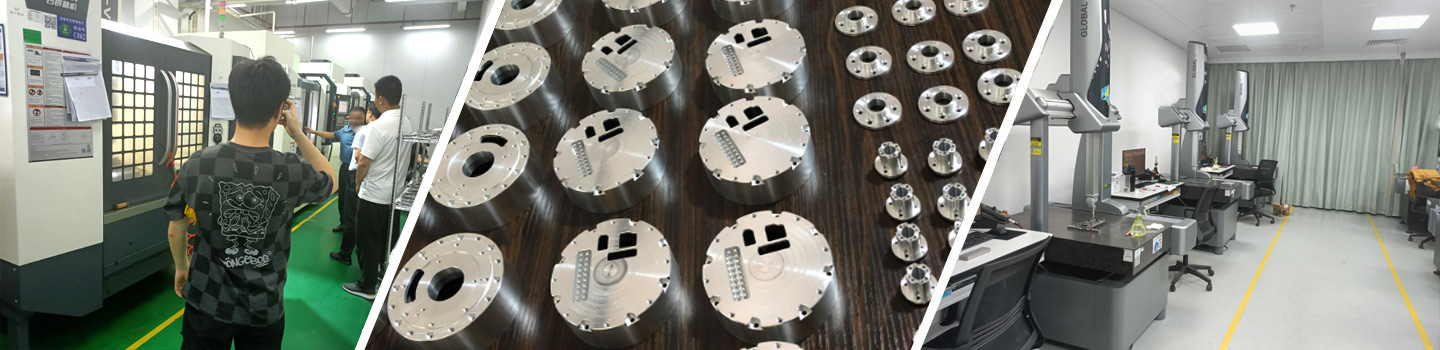

We are committed to the shortest delivery time to provide customers around the world with the highest quality at the best price. 1. Prototyping Prototyping is one or more functional templates which are made according to the product appearance drawing or structure drawing without opening the mould, and used to check the appearance or structure rationality. According to the different equipment used, the CNC hand board can be divided into laser rapid prototyping (SLA and machining center (CNC) and (3D Printing) . CNC( prototyping): Stable Quality, high accuracy, high repetition accuracy, can be processed. The advantage of CNC (prototyping) which can reflect the information expressed in the drawing very accurate, and the quality of product surface is high, especially with the finishing treatment of spraying and screen printing, even more brilliant than the products with opening the mold. Therefore, CNC milling have become the main stream of prototyping manufacturing industry. 2. Sheet Metal Sheet metal is the process of stamping some sheet metal by hand or in a die to produce plastic deformation, forming the desired shape and size, and further by welding or a small amount of mechanical processing to form more complex parts, usually, the four most important steps in sheet metal processing are shearing, punching/cutting, folding/winding, welding, surface treatment, etc. . With the more and more extensive application of sheet metal, the design of sheet metal parts has become a product, which is an important link in the development process. Sheet metal has the characteristics of light weight, high strength, conductive (can be used for electromagnetic shielding) , low cost, good mass production performance, etc. , for example, in computer case, mobile phone, MP3, sheet metal is an essential component. 3. Low Volume Production Due to the wide range of batch production, it is usually divided into "mass production" , "medium batch production" and "small batch production" . Small batch production refers to the production of a single product which is basically a special product with small batch demand. One-piece small batch production is a typical order-oriented production, its characteristics are similar to one-piece production, customarily called "one-piece small batch production" . Therefore, in a sense, the "one-piece small batch production" , more in line with the actual situation of enterprises. 4.Rapid Tooling Rapid tooling is a good way to simplify the structure of mould , also save the cost and lead-time, which used in the field of rapid injection moulding, based on the low-volume order requirement. 5. Silicone Molding Make master patterm, which can be made of any stable material, use the master to make a product shape in the silicone mold, then there is a hollow cavity leave in the mold, this will be an exact comformity of the original shape. After the silicone mold has been finished, we can create a solid replica. 6. Injection Molding Injection molding is a process used in manufacturing that produce parts from plastic materials. The material that is heated and melted, injected into the mold cavity of an injection molding machine, after being cooled and solidified, a plastic molded product is formed. 7. 3D Printing The processing of 3d Printing: 1. SLA (StereoLithography) 2. SLS (Selective Laser Sintering) 3. FDM Metal Material for 3d Printing: Stainless steel£¨316L£¬17-4£¬304£© Die steel£¨1.2709£¬CX£© aluminum alloy£¨AlSi10Mg£© Titanium alloy£¨TC4£© Plastic Material for 3d Printing: Resin PA12 PA12+GF ABS 8.Finishing Painting, drawing, electroplating, laser carving, etching, silk screen, polishing, anodizing The purpose of product surface treatment is to meet the requirements of corrosion resistance, wear resistance, decoration or other special functions. 9.Quality Control In order to ensure the quality of products, the company is also equipped with three-dimensional, projector, altimeter and other measuring tools. We can provide the CMM report based on your requirements. 10.IC Vendor Our expertise has allowed us to become a trusted partner for major IC manufacturers. We assure 3-5days lead time and provide the inspection report to keep the quality. Below are a few of the major IC manufacturers we have partnered with to provide a massive selection of parts for you to access.

|

|

|